Earth Crust Engineering

To make a sustainable development in the human society, novel technologies are required for developing various resources and ensuring long-term integrity of structures in a rock mass. Based on the rock mechanics and integrating different knowledges from various academic fields, such as fracture mechanics, fluid mechanics, and physical chemistry, we promote various investigations to contribute the development of new technologies to overcome various difficult conditions.

Academic Staff

Yoshitaka NARA

Associate Professor (Graduate School of Engineering)

Research Topics

Research Topics

When designing sub-surface structures in a rock mass, it is necessary to consider their long-term stability. In addition, the networks of fractures allow rocks to store and transport fluids, which can then interact with rock-forming minerals and enhance rock deformation processes, leading to slow, progressive fracturing. For these purposes, understanding brittle deformation and fracturing in rock is essential. In order to contribute to the long-term stability of structures in a rock mass and ensuring the safety in the developing various energy resources, I am conducting studies related to the deformation, fracturing, and fluid flow in rock. Specifically, I am investigating influences of environmental conditions (e.g., temperature, humidity, and water) on physical, mechanical, and transport properties of rock.

Contacts

Room 355, Bldg. C1, Katsura Campus, 615-8540, Kyoto, Japan

TEL: +81-75-383-3210

E-mail: nara.yoshitaka.2n kyoto-u.ac.jp

kyoto-u.ac.jp

Naotoshi YASUDA

Associate Professor (Graduate School of Engineering)

Research Topics

The main focus of the research is on the seismic evaluation and maintenance of rock structures, such as tunnels. Recent research topics are as follows:

・Analysis for seismic response of underground structure

・Evaluation of effect of voids behind the lining

・Inspection of the concrete structure by laser excited vibration

・Study of a tunnel with controlled water drainage pressure

Contacts

Room 356, Bldg. C1, Katsura Campus, 615-8540, Kyoto, Japan

TEL: +81-75-383-3211

E-mail: yasuda.naotoshi.3x![]() kyoto-u.ac.jp

kyoto-u.ac.jp

Research Topics

Influence of surrounding environment on fracturing in rock

It is essential to ensure the long-term integrity of a rock mass surrounding structures, such as the repository of radioactive wastes, the cavern to store liquified petroleum gas or natural gas, or the underground power plant. For the construction of these structures in the underground, the evaluation of long-term strength of rock is required. Therefore, it is important to investigate the time-dependent deformation and fracturing in rock under various environmental conditions.

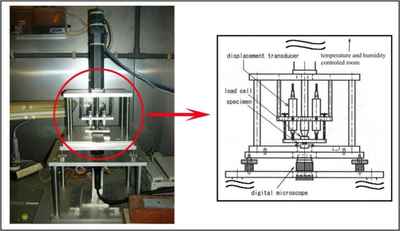

We have investigated slow crack growth (subcritical crack growth) in rock using a fracture mechanics test called "Double Torsion method". Specifically, the influence of surrounding environment on the crack velocity has been investigated. Fig. 1 shows the photo and the schematic illustration of the apparatus for Double Torsion test.

For our investigations, the influence of the environmental condition on the change of the crack velocity. It has been clarified that the crack velocity in rock in water is much higher than that in air. If the relative humidity increases, the crack velocity in rock increases in air. The crack velocity decreased when the concentration of calcium ion in water is high. It is concluded that the influence of the surrounding environment on the crack velocity in rock must be considered carefully to ensure the long-term integrity of a rock mass.

Fig. 1. Apparatus for Double Torsion test